About Me

Welcome to my portfolio! Here you can explore my journey, skills, and projects as an Aeronautical Engineering student and Product Development Engineer Intern.

Projects

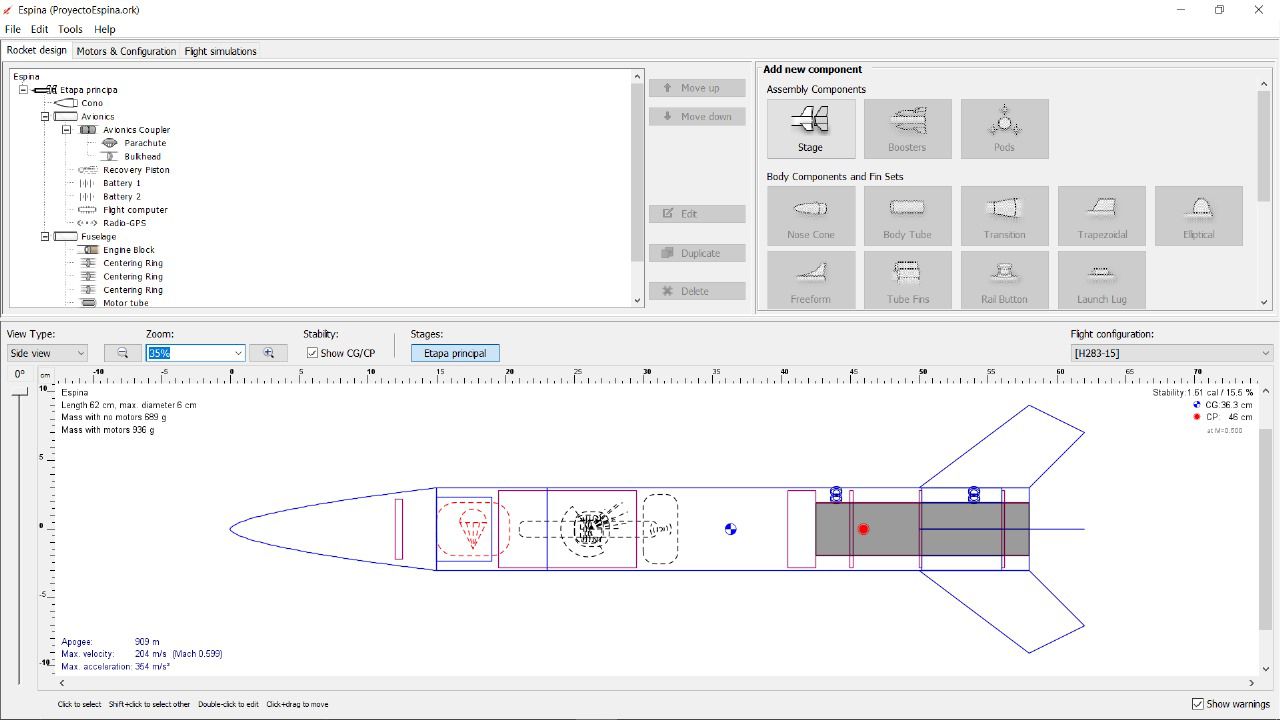

DynX Rocketry Team – Sponsorship and High-Power Rocket Development

Led administrative management and secured the resources needed to achieve the team’s funding goals. Demonstrated leadership, project management, and problem-solving skills in a highly technical environment.

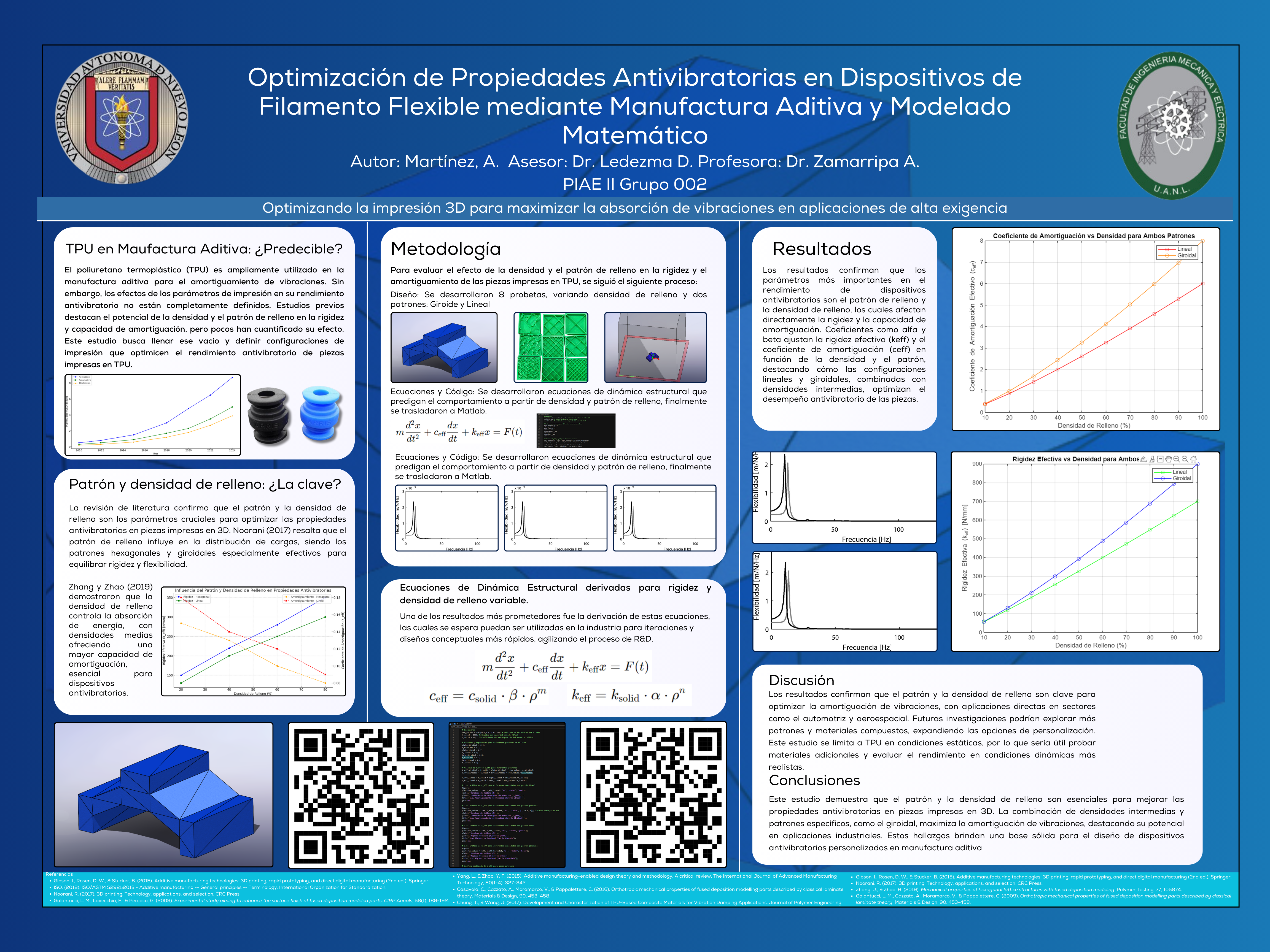

Development of Antivibration Insulators Using Additive Manufacturing

Project focused on optimizing additive manufacturing parameters to create effective antivibration insulators using flexible materials like TPU. Involved CAD design, advanced manufacturing techniques, and data analysis for performance improvement.

Internship at International Motors – Product Development

Gained hands-on experience in innovative product development for the automotive industry, optimizing design and engineering processes and applying expertise in mechanical design and manufacturing.

High-Power Rocketry Design and Testing

Actively participated in the design, construction, and testing of high-power rockets, showcasing technical skills in fluid dynamics, structural design, and collaborative work in large-scale projects.

Research and Optimization of 3D-Printed Structures

Designed and analyzed 3D-printed structures for aerospace and automotive engineering applications, highlighting expertise in design tools, simulation, and innovation.

Sustainability-Driven Engineering Initiatives

Personal or academic projects focused on integrating sustainability into design and manufacturing processes, underscoring a commitment to responsible and technological solutions for global challenges.

Articles and Blogs

Optimizing Vibration Isolators with Additive Manufacturing: Mathematical Models and Industrial Applications

Vibration isolators play a critical role in modern engineering, reducing noise, increasing durability, and improving performance across industries. This article explores how additive manufacturing and mathematical models create tailored solutions for industrial needs. Read More

Optimizing Vibration Isolators with Additive Manufacturing

Introduction: Vibration isolators play a critical role in modern engineering, reducing noise, increasing durability, and improving performance across industries such as automotive, aerospace, and electronics. However, optimizing these devices remains a challenge due to the complex relationship between material properties and design parameters.

This article explores how additive manufacturing, commonly known as 3D printing, combined with a robust mathematical model, provides a pathway to designing highly efficient vibration isolators. By analyzing the influence of key parameters like infill density and internal patterns, this study demonstrates how these devices can be tailored for specific industrial applications.

Background and Relevance: Additive manufacturing has evolved from a rapid prototyping tool to a transformative technology for producing functional components. Its ability to create complex internal structures has made it an ideal method for manufacturing vibration isolators. Parameters such as infill density and internal patterns significantly impact dynamic properties, including stiffness and damping.

Methodology: Mathematical Model: A mathematical framework was developed to predict the dynamic performance of vibration isolators. Key equations relate effective stiffness (keff) and damping (ceff) to infill density and internal patterns. Configurations Studied: Two internal patterns—linear and gyroid—were analyzed. Linear structures were evaluated at infill densities of 15%, 45%, 60%, and 90%, while gyroidal structures were tested at 10%, 35%, 60%, and 80%.

Results: Gyroid Patterns: At intermediate densities (60%-80%), gyroid patterns achieved an optimal balance between stiffness and damping, making them ideal for applications requiring vibration absorption. Linear Patterns: Linear structures demonstrated superior stiffness, suitable for applications prioritizing rigidity over damping.

Portfolio

Design CAD

Highlights from my CAD design projects.

Simulations

Simulations conducted using ANSYS and MATLAB.

Prototypes and Tests

Prototypes created and tested for engineering applications.

Services

Custom CAD Design

Offering tailored CAD solutions for your projects.

Simulation and Analysis

Providing insights through engineering simulations.

Prototyping

From design to tangible prototypes, I bring ideas to life.

Recognitions

HPR L1 Certification

Certified in High-Power Rocketry Level 1.

ANSYS Advanced Training

Completed advanced training in ANSYS simulations.

ENMICE Competition

Participated in national cohete design competitions.

Store

3D Printed Models

Purchase unique 3D-printed designs.

Engineering Renders

High-quality renders for your engineering needs.

CAD Templates

Downloadable CAD templates and resources.

Contact Me

If you'd like to collaborate or learn more about my work, feel free to reach out:

Email: antmarvalero@gmail.com

Academic Email: antonio.martinezvlr@uanl.edu.mx

My Linkedin: www.linkedin.com/in/antonio-martinez-valero